There is a wide range of finishing alternatives available for the purpose of refinishing and/or sanding. Two of the most popular finishes are tung oil and polyurethane. It can be difficult to ascertain which one is better than the other – this, actually, is a subjective decision.

See Also:

This is due to the fact that such a choice is made on the basis of the properties and advantages of the material which is adequate for the client’s current and immediate needs of beginner woodworking projects.

More...

About Tung Oil

Tung oil (also known as China wood oil) is procured from the Tung tree – from the seed of the nut of the tree. Believed to have been discovered in ancient China, it is see-through and its close to moist appearance is due to its property of hardening after coming in contact with air.

This oil is mainly used for covering and the finishing of wood products and, often, after multiple applications, can pass off as plastic.

Linseed, poppy, and soybean oils are some of the similar oils. A fine wrinkled finish is what the raw tung oil dries to become – this was used to advantage for making wrinkle finishes by using extra cobalt drier.

The oil is boiled to make it gas-proof ‘– most of these oils are made gas-proof nowadays. This is why tung oil is these days “heated” to prevent wrinkling.

Tung oil is often synonymous with any wood finishing product in the paint and varnish industry that has bona fide tung oil in order to give a finish that is similar to the finish that tung oil would give.

Tung oil via notrashproject

Tung oil helps achieve a really vintage and regal wood finish look. These kinds of finishes are the favored options by the professionals. It supersedes the layers of wood, creating an internal link, becoming almost a part of the wood.

This causes the finish to become water and dirt resistant. The tung oil finish emphasizes the grain particles of the wooden surface, causing it to look polished and beautiful.

About Polyurethane

Polyurethane (PUR and PU) is polymer of organic units connected by urethane (carbamate) links. The majority of these polyurethanes are of the thermosetting kind, there are also thermoplastic types of polyurethanes available.

These polyurethanes are usually created by reacting a di/poly-isocyanate along with a polyol. Polyurethanes usually have at least two functional groups per molecule due to the polyols and isocyanates.

Due to the high toxicity issues of these isocyanates, there have been attempts to reduce the usage of isocyanate and synthesize polyurethanes. To minimize the health and environmental problems, polyurethanes devoid of isocyanate have been formulated as a new group of polyurethane polymers.Polyurethanes are also known urethanes.

This is not to be confused with ethyl carbamate, which is also called urethane, as polyurethanes do not have ethyl carbamate and neither are they made from it.Strong foam seating, resilient foam insulation panel, long lasting elastomeric tires, and wheels are some of the things produced using polyurethanes.

Polyurethanes have two kinds of bases: oil and water. Oil-based polyurethane is usually preferred over the water based one as it suits wooden surfaces more. This kind of polyurethane is more lustrous than its water-based counterpart and does not need as many refinishes either.

It is also more appealing and cost effective.Water based polyurethane is not as lustrous and is not as great as oil based polyurethane. Due to the minimal amount of solids in the former, four coats are required for the water borne polyurethane, instead of the oil-based polyurethane.

There is a necessity for the application of several extra coats after every few years. However, this kind of polyurethane is also advantageous in many ways. It dries up a lot more easily than its oil-based counterpart which, in turn, means that it is a lot less time-consuming.

Additionally, it does not smell as much as the oil based polyurethane either.

Tung Oil versus Polyurethane: The Difference

Penetrating into the layers of the wood surface, tung oil can take up to two days to dry completely. To top it, around seven coats of tung oil are needed to make it water resistant. Lastly, surfaces finished with tung oil need additional touch ups all year round to retain its original quality.

Unlike tung oil, polyurethane rests on the top layer of the wooden surface. It takes around half a day’s application. Additionally, it requires only two coatings of polyurethane to make the wood surface waterproof.

Tung oil via tungoil

Tung oil can be applied to the wood surface using a normal piece of cloth whereas polyurethane has to be applied using a sponge or paint brush.A granular and rich look is obtained through the use of tung oil as a finish. This is due to the fact that its coating technique is not like that of polyurethane.

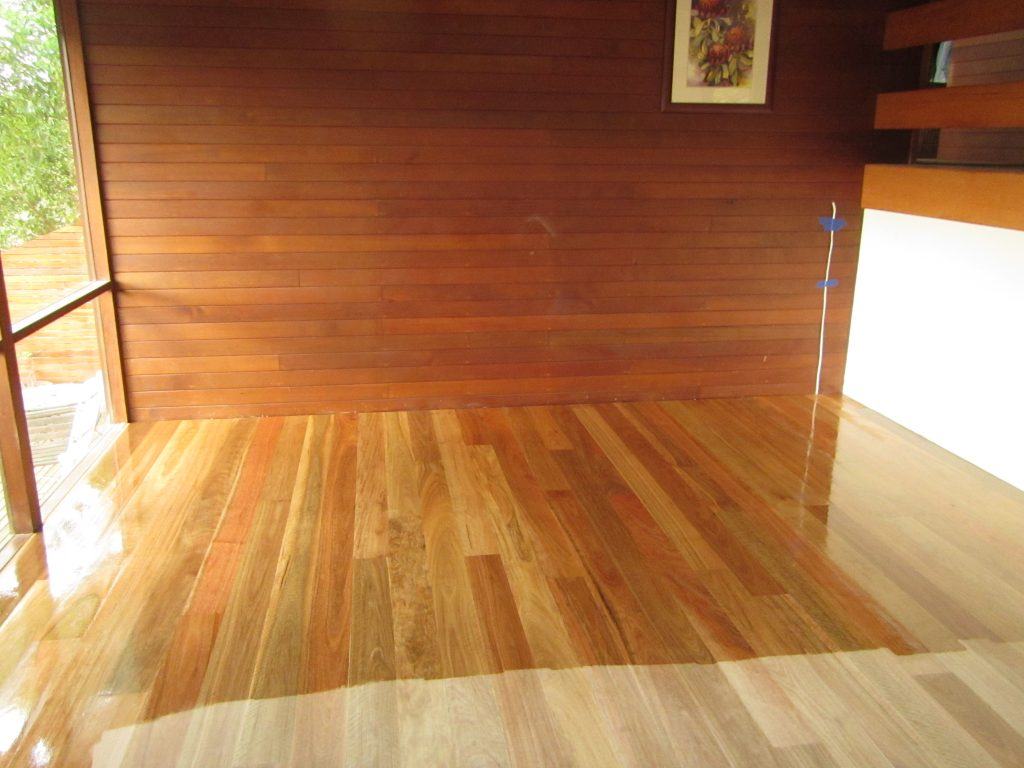

Polyurethane finish is believed to be the best alternative for mainly excessive traffic exteriors. This includes surfaces like wooden floorings among other things.

At the same time, however, a polyurethane finish is not the most suited option for more detailed woodwork – such as furnishings among other things – due to the prominent glaze, it leaves on the top of the concerned material.

Tung oil is a much better choice for such detailed items due to its trait of pervading through the layers of wood, instead of merely coating it like a polyurethane finish would.In terms of comparison, one of the most glaring cons of using polyurethane over tung oil for finishing would be the tricky method of its usage.

Tung oil via ordinary-2-extraordinary

A surface at least relatively devoid of dust is necessary as the smoothness of the finish depends on the smoothness of the surface. This is mainly due to the fact that any overlooked dirt particulate if it remains on the wood whilst application, will be trapped there forever.

Also, there is also an equal need to be cautious about the quality of brush used for application as any stray brush bristle can also get caught within the finishing layer.