If you have shed to store things, then shed ramp is necessary structure you need to build. Building sheds makes sense when we consider how can it ease the moving things in and out. Most of the things that we need to move are snow blowers, lawn mowers, rolling fertilizer spreaders and bikes.

See Also:

It is obviously easy to move huge things on ramp as compared to stairs. Literally speaking, anything serving the purpose can be your ramp such as a board ramp on floor in front of gate that can support the weight of machinery.

More...

How To Build A Shed Ramp?

But a structure build with proper planning, structure and strength can serve the purpose with durability and reliability for longer period of times. Moreover, it can also avoid so many unexpected upsetting consequences as well.

Free Shed Ramp Plans

Ramp Plans

Build a Shed Ramp via TedsDixieSheds

If you are considering a ramp for your shed, the first thing to consider is a sound plan. Planning step may include from material selection to size and height required.

Shed Ramp via GardenShedPhansOnline.com

The quality of shed depends upon the plan you make so it is the most important foundation step that is mostly overlooked.

There are such a large number of outlines and plans to look over when building ventures for your terrace that we truly prescribe you to work with consideration and to choose the undertakings that suit your requirements and fit inside the financial plan.

simple shed ramp

Let's Investigate the related activities and begin increasing the value of your property.

Picking The Ramp Slant

Wood Shed Ramp Details via CheapSheds.com

As a major aspect of your shed arranging you ought to ensure that there is adequate space before the shed for the get to ramp. The length of the ramp will be represented by the range from the outer ground level to the shed floor and the slant that you pick.

A tiny bit of thought needs to go into the ramp, for two reasons - security and usability.

Security

Safety Ramp via secrets-of-shed-building.com

The more extreme the ramp, the less demanding it is to slip or excursion. It in all probability won't be you (as you fabricated it and know its pitfalls) however one of your friends and family will. So 'listen up'.

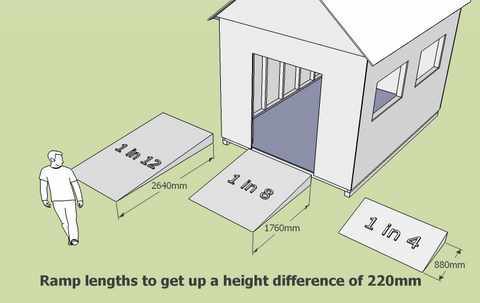

The steepest ramp for an open slope is one in twelve (1:12) which is represented by usability for wheelchair clients.

For use by the overall population many construction regulations suggest a most extreme slant of 1:8 (that is one inch ascend for each eight inches on a level plane.)

With a 1:8 ramp, if the floor is nine creeps over the ground, the slope will be 72 inches long (1.83m long). It is conceivable to go more extreme, up to around 1:4 for fit capable individuals in the event that you need to, however do recall the expanded danger of slipping.

Usability

Solving ramp problem via Jays Custom Creations

The other component to recollect is the geometry of the hardware you are to utilize.

In the event that you are utilizing a ride-on lawnmower or garden tractor they will have a lot of energy to get up the ramp yet you have to consider if the machine will ground in the center as the undercarriage of the cutter goes over the entryway edge.

In the event that you are utilizing a snow furrow, the sharp edge may keep running into the ramp before the wheels if the slant is excessively steep! To decide the basic ramp check in the hardware manual or do some site tests.

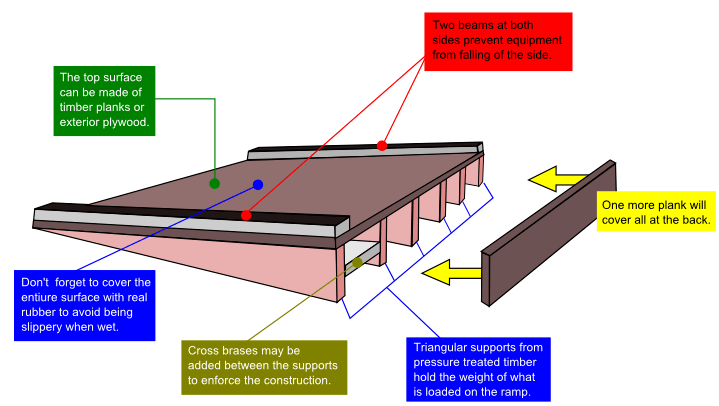

Make the shed ramp no less than six inches more extensive than your entryway opening on both sides. This gives a touch of resilience in going in and out, utilize this space to settle a kerb to the slope (stops the trimmer sliding off).

Ramp Surface

Wood Shed Ramp via thoughts from arealdeal

A wooden shed slope will get to be distinctly elusive after some time as it gets wet and green growth develops. The slip or slide resistance of the slope surface can be enhanced in various ways:

The pro paints are defined with coarseness sizes and paint that work. The homegrown variant of this is to utilize outside review paint and sprinkle on some coarse sand.

The other alternative is to utilize a move of electrifies chicken wire or extended metal sheet and staple this down to the slope surface utilizing stirred staples.

It is proposed to make the ramp as shallow as could be allowed, this will keep away from numerous wellbeing and handy and get to issues

Materials Suitable For Shed Ramp

Shed Ramp via instructables

Different materials can be used to make update shed ramps. The important thing to consider while selecting the material for shed is the weather conditions and other environment factors.

Moreover, the material must be strong enough to withstand the weight of your machinery and equipment you need to roll over it.

Mostly wood planks are used for shed ramp but if you need a more permanent structure then iron ramps or permanent concrete structures also serve the purpose. Making a fully professional ramp.

The key is to invest in high quality materials having the properties like pressure-treated lumber and weather-resistant). Its only then you can get professional results.

Here we are going to guide you to make a customized wood shed ramp so next time you need to move things in and out of your shed, you may ease your loadings.

Materials Needed

wood plank

Deck Screws

- pressure treated 2 x 6? wood plank

- pressure treated 2 x 4? wood plank

- 1 lb. flat head #9 Deck Screws, click here to find out.

- Simpson Rafter Hangers LSU26, or equivalent (1 for each stringer), click here to check them.

- Washers, click here to find out

- 5/4 deck boards, click here to see it on Homedepot

- Galvanized screws. Click here to check the screws on amazon

- A Power Drill

- A Hammer

Follow These Steps To Build A Shed Ramp

Shed Ramp Design

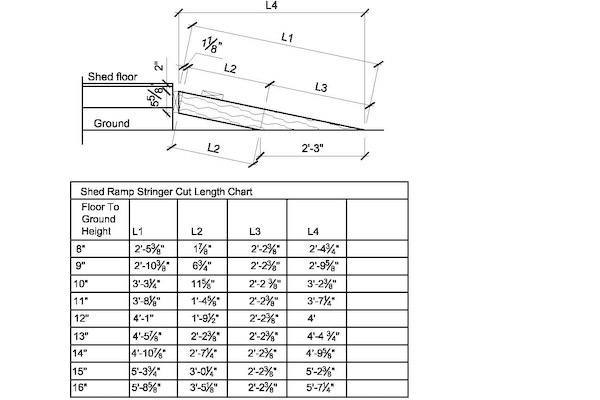

Shed Ramp Stringer Cut Length Chart via iCreatetables

Design your ramp with taking into account all the measurements. Make draft on chart that can save much time and errors. Find out how much width you need your ramp to extend.

Mostly, it goes to 5-7 inches’ past door opening either side. Length of ledger board is actually the width of the ramp. Mark the highest point of the record board area on the shed divider.

The highest point of the ledger board will sit 2" beneath the shed floor height so that when the decking sheets are introduced there will be a smooth move between the principal deck board and the shed floor.

Make The First Stringer

Measure and Cut “Stringers” via ONE PROJECT CLOSER

Use your chart drawings of draft you had made to put markings on first encountered stringer board. Then start Cutting along markings made earlier to ready the first primary stringer board.

Use a square of wood to reproduce the record board. Hold the square of wood on the shed divider and set the stringer on the piece to ensure that the base point lays equitably on the ground.

Use First Stringer as Pattern Stencil

Use First Stringer as pattern stencil via ONE PROJECT CLOSER

Getting first stringer board ready, upto the required measurements is basically the difficult task but once it is done you can use it to make other boards of same measurements. Your first stringer board may be used as a stencil for cutting.

For that set the principal stringer against the wood to be utilized as one of alternate stringersOutline the stringer on the new board. Cut out the new stringer according to the pattern.

Repeat with the rest of the stringers.

Assemble Ledger And Ramp Stringers Together

Anchor Stringers via ONE PROJECT COLSER

The next step needs some assembling finally. This step requires you to combine different boards to come up with some good reliable shape. Layout the stringer areas on the ledger board by separating the stringer areas uniformly on the ledger board.

Attach the stringers to the ledger board utilizing 3" deck screws. Utilize 3 screws to screw from the substance of the ledger board into the top finishes of the stringer.

Attach The Shed Ramp To The Shed

Attach the Shed Ramp to The Shed via ONE PROJECT CLOSER

Put ledger boards and stringer structure against shed wall underneath the entryway hanging in the balance you drew during laying out ramp height.

Use deck screws (3’’) to join the record board to shed wall. Utilize 3 screws each 12 creeps along ledger board.

Mount Simpson Rafter holders at every stringer. The end holders will keep external edges leveled and together with nails to finish of all ledger board.

Ramp Deck Installation

Block In Between Stringers via ONE PROJECT CLOSER

Measure decking sheets and slice them to the marked length. They ought to be of similar length as for ledger board.

Beginning at top point of ramp and introduce the main board. The board may be angle in certain way so there remains no hole between the highest point of the slope and shed floor. Mount deck sheets down the slope with no less than 1/8" crevice between sheets.

It is best to put every one of the sheets on the slope in their individual areas and modify them to crevices are equivalent and afterward tie them to ledger sheets utilizing deck screws. Tread that joins with ground having an angle cut to make it smoother from ground to slope.

There is practically zero wood toward the finish of stringers to append the base tread to so it is commonly good to hold over the stringers. Use not less than 2 screws to assemble decking tread around the stringers.

Non-Slippery Surface Built

Cut Ramp Boards via ONE PROJECT CLOSER

Shed ramps may be elusive when wet. At the point when fabricating shed ramp, introduce a non-slippery surface over deck sheets. There is glue supported non-dangerous stair step stickers that are easy to be utilized on top of the point of the slope.

Also, floor paints which have sand incorporated in them in order give a non-slippery covering.