A common question asked by wood workers is what is the difference between a jointer and a planter? So here’s a detailed discussion on these two types of tools that would help you in this respect:

See Also:

More...

PLANER VS JOINTER: GENERAL OVERVIEW

There are certain ways to determine whether you will need a Jointer or planer. Generally wood workers need both planer and jointers for working with power tools.

Lumber can be brought in shape in many different ways but the jointer and the planer are the most used tools.

For a raw piece of lumber the jointer is the preferable tool that gives it a square face and one flat square edge. The planer makes both the sides of the wood parallel.

There are certain questions which a wood worker should ask himself before deciding planer vs jointer.

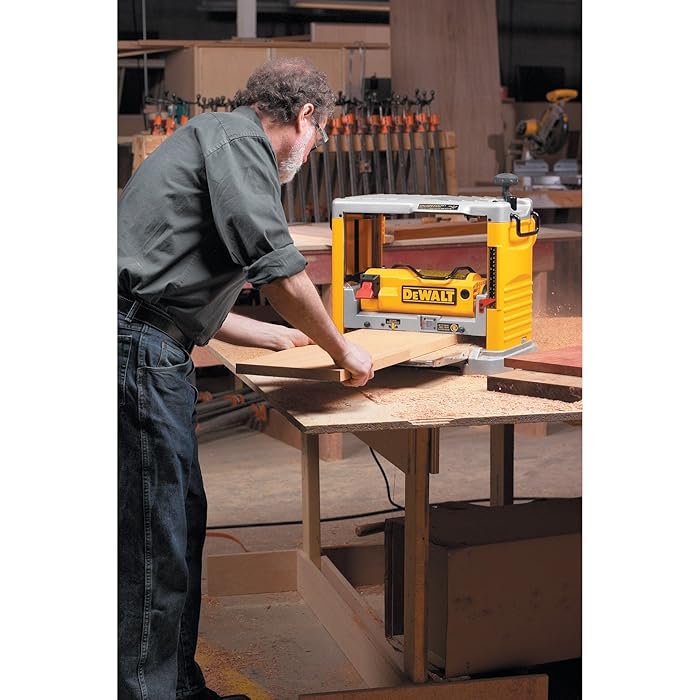

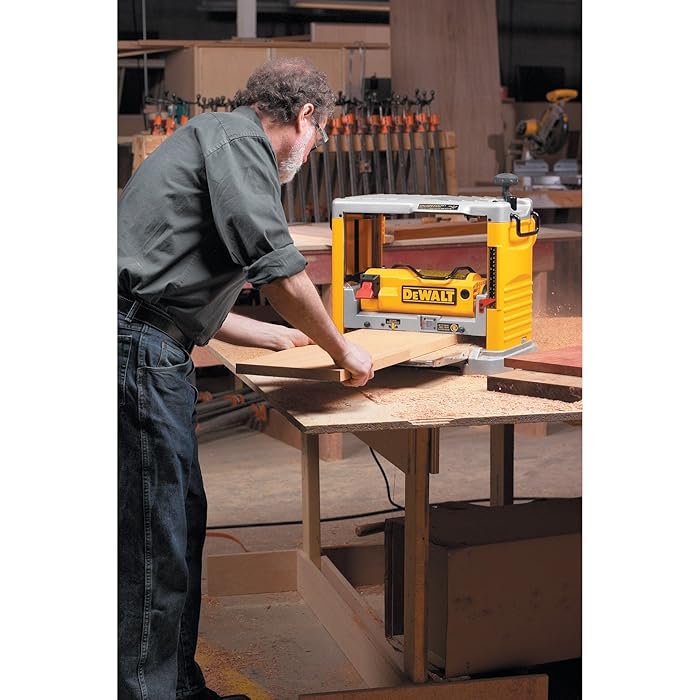

DEWALT DW734 15 Amp 12-1/2-Inch Benchtop Planer via Amazon

- The Type of Wood: If you are working with S2S, S3S, S4S types woods which come with 2, 3 or 4 surface planed then all you need is a jointer which is good, but while working with rough lumber a planer should be your priority.

- Checking the Edge and Surface of the Wood: To check the edge and surface of the wood, whether it needs the use of a jointer for smoothening.

- The flatness of the wood should be checked, whether to use the jointer should be used to flatten the piece or the planer should be used to flatten the piece along its curve line.

- The length and the thickness of the wood for the project should be determined beforehand. This will help in deciding whether the jointer will be needed to fix edge of different pieces of lumber together or the planer will be needed to bring the lumber to the required thickness.

- Decide whether a parallel plane surface is needed that a planer can easily yield.

- Check the lumber for imperfections, so that it can be fixed with a planer.

- Check the lumber for twisted edges and surfaces, which can be corrected with a jointer.

PLANER

Planer is a tool used for thickening wood, such as a wood to be joined flat should be thickened end to end.

Functionality is simple but the mechanical execution is complicated. All planners have limit to the amount of wood that can be removed in one pass through the cutter.

JOINTER

A jointer basically derives its name from its primary function i.e. is of producing flat edges on boards before joining them the edge to edge before producing much wider boards.

A jointer is a tool used for creating flat surfaces or straight surfaces as well as to square edges. In the complete setup of the jointer, there is an infeed table and outfeed table aligned in the same line.

A cutter head along with the knives is set between the tables and the top of the knives is aligned at flush with the outfeed table.

WHICH ONE SHOULD YOU GET, A PLANER OR A JOINTER?

Jointer and planer are such power tools which serious wood workers and DIY’rs generally use. Whether you need both the tools or not is also a valid question.

Yes, both the tools are needed because a planer can do the work of a jointer but it will not be perfect as needed.

Ridgid JP0610 Planer, 6-1/8-Inch Jointer via Amazon

So, the jointer is a tool which gives you a flat side and a flat edge. What about the other side and the edge? This is the point where the planer comes into action. It flattens both faces and edges of the lumber and makes both the sides parallel.

Even the jointer can flatten both sides of the lumber for you but they won’t be parallel to each other and will be left with a piece which maybe thick at one end and thin on the other side.

Looking To Buy?

Buying a planer or a jointer is not such a tough call as in the case of other power tools. We have provided you with a list of planers and jointers to select from.

Top Picks in PLANER

Dewalt DW734 15 amp 12-1/2 – Inch Bench top Planer

DEWALT DW734 15 Amp 12-1/2-Inch Benchtop Planer via Amazon

- Three knife cutter-head

- 15Amp motor delivering 15000 revolutions per minute

- Quick accurate depth adjustment

- 96 cuts per inch

- 3-year warranty

- 30 percent more knife life as the knives are disposable and reversible.

- Four column

- Super convenient and user-friendly DIY machine for the garage

- Reliable tool

Makita 2012NB 12-inch Planer with Interna-Lok Automated head Clamp

Makita 2012NB 12-Inch Planer with Interna-Lok Automated Head Clamp via Amazon

- 1 year warranty

- Compact with less weight for easy transportation

- Faster easier blade exchange feature

- Operators Comfort maintained by low decibel value of 83db

- LED light indicator on power connection

- Large table extension supporting the work piece

- Double edge planer blades

- Optional dust hood system

- On/off paddle switch easy to operate and large as well

- Detachable tool box to store standard equipment

- 4 post design for stability

- Diagonal cross supports for stability

- Ideal for the amateur garages and wood working stores

- Quality of cut is better than Dewalt

Delta Power tools 22 55513 In portable Thickness Planer

Delta Power Tools 22-555 13 In Portable Thickness Planer via Amazon

- An expensive option

- 5-year warranty

- Reversible dust port allowing you to collect chips from the left and right side of the planer

- To reduce snipe and support long pieces there are adjustable infeed and outfeed tables

- 4 column design for stability

- Quick change knife system

- Dual edge disposable knives with any difficulty to use alignment jigs

- Has a corded electric power source

- Simple to operate and maintain

- User friendly

Top Picks in JOINTER

Ridgid JP0610 Planer, 6-1/8 – Inch Jointer

Ridgid JP0610 Planer, 6-1/8-Inch Jointer via Amazon

- This item is a jointer cum planer

- Versatile bed table

- Dual bevel fence

- 1 hp heavy duty motor

- Used for tools replacement parts

- Corded electric power source

Jet JJP- 10 BTOS 10” jointer

Jet JJP-10BTOS 10-Inch Bench-Top Jointer/Planer via Amazon

- The biggest in budget jointer

- Biggest budget jointer

- Not for the professional wood worker

- Great for the DIY wood worker

- 11000 revolutions per minute

- 1-year warranty

- Cutting angle of 0-45 degree

BOTTOMLINE

While concluding we can say that a planer and a jointer are two completely different tools and an average wood worker generally needs both the tools. But as we summarize we can see that the planer should be brought first.

Whichever tool you use, safety is a major issue. While using a jointer or a planer wearing safety glasses is a must or may be a face shield. Wearing an ear protection suitable for the frequency of noise you are exposed to and wearing protective footwear’s while working is also quite important.

The start and stop button of the machine should be in reach of the operator. When you are done with the tool never leave the machine running and check if the cutting head has stopped revolving before you leave.

Do not press hands over the cutter, and don’t even try to clean the dust particles from the table with hand or compressed air, only brushes should be used for the purpose..